The Role of CAD/CAM Software in CNC Machining

- Calvin Wu

- May 3, 2023

- 3 min read

Outline:

1. Introduction

a. The importance of CAD/CAM software in CNC machining

b. Overview of CAD/CAM software functions

2. CAD: Computer-Aided Design

a. 3D modeling and design

b. Simulation and analysis

c. Design optimization and revisions

3. CAM: Computer-Aided Manufacturing

a. Toolpath generation and G-code

b. CNC machine programming

c. Automation and efficiency

4. Advantages of Using CAD/CAM Software in CNC Machining

a. Improved design and manufacturing accuracy

b. Streamlined workflow and reduced production time

c. Greater flexibility and customization

5. Applications of CAD/CAM Software in Various Industries

a. Aerospace and automotive

b. Medical and dental

c. Jewelry and consumer goods

6. The Future of CAD/CAM Software in CNC Machining

a. Ongoing innovations and advancements

b. Industry trends and predictions

Introduction

The success of CNC machining in modern manufacturing relies heavily on the use of sophisticated CAD/CAM software. This powerful tool has transformed the way products are designed and manufactured, offering greater precision, flexibility, and efficiency. In this article, we'll delve into the functions of CAD/CAM software, its applications across various industries, and how it's shaping the future of CNC machining.

CAD: Computer-Aided Design

1. 3D Modeling and Design

CAD software enables engineers and designers to create detailed 3D models of their products, providing a comprehensive visual representation of the final product. This virtual model allows for easy manipulation and fine-tuning, ensuring optimal design before manufacturing begins.

2. Simulation and Analysis

Using CAD software, designers can simulate the behavior of their designs under various conditions, such as stress, temperature, and wear. This enables them to identify potential issues and make necessary adjustments to ensure the durability and performance of the final product.

3. Design Optimization and Revisions

CAD software allows for easy design revisions and optimization, enabling designers to make quick changes and improvements without starting from scratch. This streamlines the design process and ensures that the final product meets all necessary requirements and specifications.

CAM: Computer-Aided Manufacturing

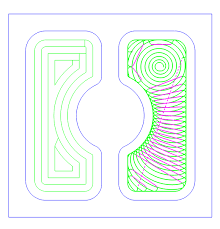

1. Toolpath Generation and G-code

CAM software generates toolpaths and G-code, the programming language used by CNC machines, based on the 3D models created in CAD software. This ensures that the CNC machine follows the exact specifications of the design, resulting in precise and accurate manufacturing.

2. CNC Machine Programming

CAM software simplifies the process of programming CNC machines, as it automatically generates the required code for the machine to follow. This reduces the risk of human error and ensures that the machine operates efficiently and accurately.

3. Automation and Efficiency

The integration of CAD/CAM software streamlines the entire design and manufacturing process, automating many tasks and significantly reducing production time. This efficiency allows manufacturers to meet tight deadlines and reduce production costs.

Advantages of Using CAD/CAM Software in CNC Machining

Improved Design and Manufacturing Accuracy

CAD/CAM software ensures a high level of precision in both the design and manufacturing phases. The accurate 3D models and toolpaths generated by the software enable CNC machines to produce parts with tight tolerances and exact specifications.

2. Streamlined Workflow and Reduced Production Time

By automating many aspects of the design and manufacturing process, CAD/CAM software streamlines the workflow and reduces production time. This results in a more efficient manufacturing process and faster delivery of finished products to customers.

3. Greater Flexibility and Customization

CAD/CAM software allows manufacturers to easily create custom designs and produce small batches of parts, providing greater flexibility and customization options for customers. This is particularly beneficial in industries that require unique, tailor-made products.

Applications of CAD/CAM Software in Various Industries

1. Aerospace and Automotive

CAD/CAM software is widely used in the aerospace and automotive industries for designing and manufacturing complex components that require high levels of precision and accuracy.

2. Medical and Dental

The medical and dental industries also benefit from CAD/CAM software, as it enables the creation of custom prosthetics, implants, and surgical instruments with precise dimensions and features.

3. Jewelry and Consumer Goods

In the jewelry and consumer goods industries, CAD/CAM software allows for the creation of intricate designs and patterns, as well as rapid prototyping and efficient production of custom pieces.

The Future of CAD/CAM Software in CNC Machining

1. Ongoing Innovations and Advancements

As technology continues to advance, we can expect to see ongoing innovations in CAD/CAM software, offering even greater capabilities and features for designers and manufacturers.

2. Industry Trends and Predictions

The use of CAD/CAM software in CNC machining is expected to grow as more industries recognize the benefits of this powerful tool. As the demand for customization and precision increases, CAD/CAM software will continue to play a critical role in shaping the future of manufacturing.

Conclusion

In conclusion, CAD/CAM software has become an essential tool in CNC machining, providing significant advantages in design, manufacturing, and customization. As the technology continues to evolve, we can expect even greater innovations and applications across a wide range of industries, further revolutionizing the world of manufacturing.

Comments