Understanding the Importance of Toolpath Strategies in CNC Machining

- Calvin Wu

- May 12, 2024

- 2 min read

Introduction

In CNC machining, the selection of toolpath strategies is pivotal for optimizing machine operations, enhancing part quality, and reducing production time. These strategies involve the planned sequence of tool movements to remove material effectively and precisely.

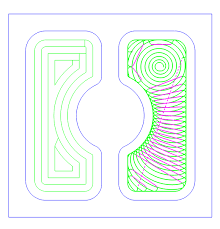

Toolpath Strategies in CNC Machining

HSM techniques involve higher feed rates and spindle speeds to remove material faster, maintaining part quality. This approach is especially effective in mold making, improving geometric accuracy and surface finish to reduce or eliminate polishing needs (BDE Inc.) (Sacher CNC).

Constant Stepover: Maintains a uniform stepover distance, crucial for achieving a consistent finish across the part.

Pencil Milling: Targets small, intricate areas and corners that larger tools might miss, enhancing detail in the final product.

Plunge Roughing: Utilizes a plunging motion, typically in the Z-axis, to remove material efficiently, which is particularly useful when dealing with harder materials (BDE Inc.) (Sacher CNC).

Benefits of Optimized Toolpath Strategies

Increased Productivity: By reducing cycle times and improving the speed of the machining process.

Enhanced Surface Quality: Optimized toolpaths can significantly improve the surface finish, reducing the need for subsequent finishing processes.

Extended Tool Life: Efficient toolpaths distribute cutting forces evenly and reduce tool wear over time.

Implementing Toolpath Strategies

To leverage these strategies effectively, CAM software plays a crucial role. Modern CAM systems are equipped with advanced algorithms that can automatically suggest optimal toolpaths based on the design geometry and required finishes. This integration of CAD/CAM technology is fundamental in modern CNC machining for ensuring precision and efficiency (BDE Inc.) (BDE Inc.).

Conclusion

The correct implementation of toolpath strategies in CNC machining not only enhances operational efficiency but also improves product quality and reduces manufacturing costs. As technology progresses, the capabilities of these strategies continue to evolve, offering even greater precision and flexibility in CNC machining operations.

For more detailed insights into toolpath strategies, you can explore further through the comprehensive discussions on BDE Inc Blog and Sacher CNC.

Comentarios